- How to edit the solder mask in sprint layout how to#

- How to edit the solder mask in sprint layout update#

And a dry application is that lay down a uniform thickness across the entire surface. The surface topography will depend on whether to use a liquid or dry application. You will need a photoimageable solder resist for most modern PCB designs.

There are some specific requirements that replace whatever else you learn on the internet.

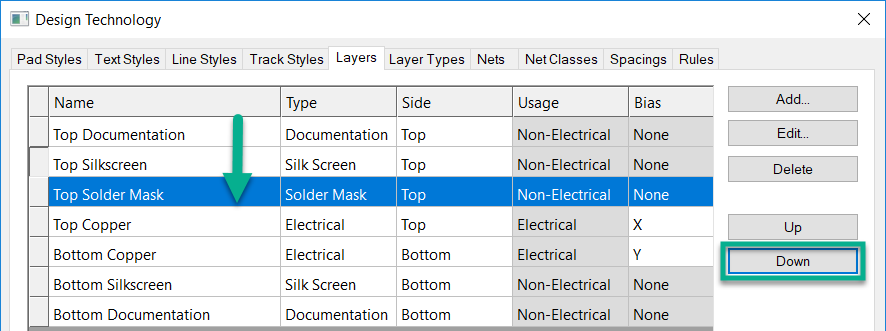

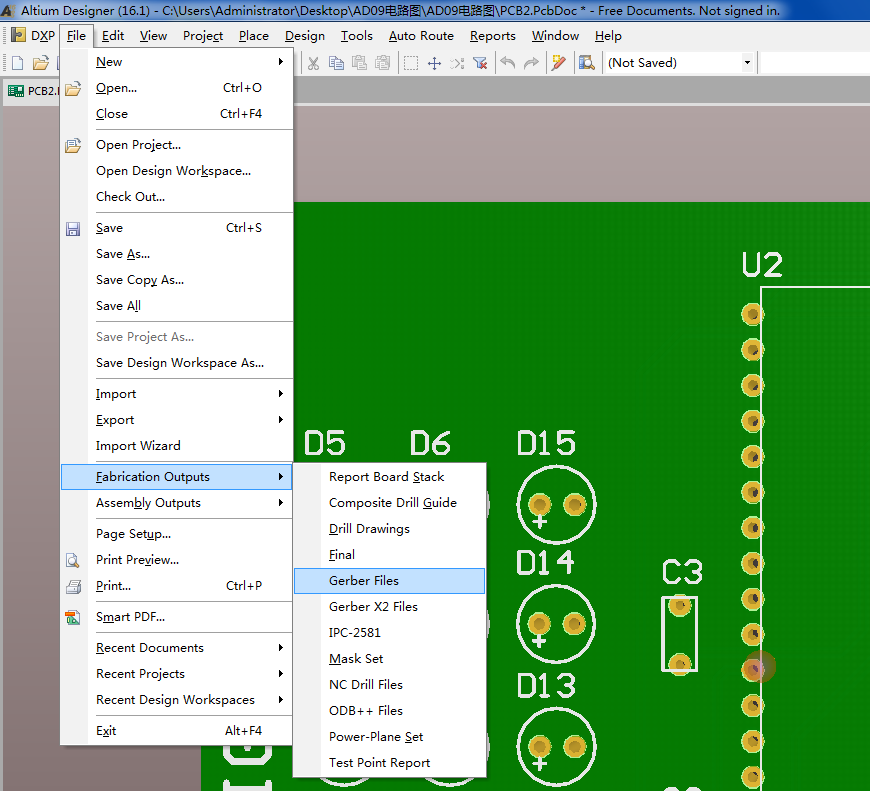

In electronic design automation, the solder mask is treated as a layer of the printed circuit board, and is described as a Gerber file like any other layer, such as the copper and silkscreen layers.Īn appropriate solder mask depends upon the physical dimensions of the board, components, holes, and conductors, the surface layout, as well as the final application for your product.įirst of all, please check the industry standards around solder mask and expected application if you have a PCB solder mask that will be used for medical, aerospace, telecom, or other “high reliability”industries. All three processes go through a thermal cure of some type after the pattern is defined.

DFSM is vacuum laminated on the PCB then exposed and developed. LPSM can be silkscreened or sprayed on the PCB, exposed to the pattern and developed to provide openings in the pattern for parts to be soldered to the copper pads. Other types are the liquid photoimageable solder mask (LPSM) inks and dry film photoimageable solder mask (DFSM). The lowest-cost solder mask is epoxy liquid that is silkscreened through the pattern onto the PCB. Solder mask comes in different media depending upon the demands of the application. Printing a liquid epoxy over the board with a silkscreen is the most fundamental solder mask option, which is like airbrushing face paint on with a stencil. There are a number of different types of mask material, the best option for your PCB according to your application and cost. Solder mask is made up of a polymer-layer that coating over the metal traces on a board. Opening needs to be made in the solder mask wherever components are soldered after applied, which is accomplished using photolithography. Solder mask is not always used for hand soldered assemblies, however it is important for mass production boards that are soldered automatically using reflow or solder bath techniques. A solder bridge is an unintended electrical connection between two conductors with a small blob of solder, and the boards can prevent this from happening with solder masks. Solder mask is a thin lacquer-like layer of polymer that is usually applied to the copper traces of a PCB for protection against oxidation, and prevent solder bridges from forming between solder pads.

How to edit the solder mask in sprint layout how to#

How to avoid making big "non-standard" pads? Just cover pads with polygon with the same signal name, for example, ground pad may be size of auto, but when you cover it with polygon they merge forming big conductive area - this way you have only small pad's copper area exposed for soldering, and remaining space covered by the solder mask.Solder mask is a protective coating for the bare board, bare boards is not only to prevent accidental solder bridging as assembly covered with mask, but also protect the board from the environment. To open some space on the solder mask - do not forget that pad is an area uncovered by the mask.I used to do it, it is normal, but as I said if there will be something wrong in the layout at the board level you will get an error. To make its solderable area bigger (most probably not smaller!).Why you may need to change the pad diameter from auto (in other words - from default rules' settings)? Default design rules are defined the way so that you would be more or less easily solder the pins, contact would be good and part would be fixed on the board well. It is a space to put solder into to fixate the component's pin. For advanced EAGLE user it would be ok, but if you are a beginner, you will get lost and hate the tool at the end. The recommendation It should not be changed prevents you making a lot of custom pads and vias which do not comply with settings on that DRC tab, and thus getting a lot of errors which you will have to manually correct in the library editor, or will need to change settings in DRC rules.

The related design rules are located in the DRC -> Restring tab, where you can set pads' minimum and maximum diameter, and percentage of their drill diameter. When in library editor, you can change diameter of the pad using info tool in the GUI.

How to edit the solder mask in sprint layout update#

Not clear from your question and from documentation - you created device in library editor, then to change this device's pad properties you need to go to library editor, do it there and then update device in the circuit/board you will not be able to make change to pad which is a part of the device in board editor.

0 kommentar(er)

0 kommentar(er)